ISRO achieves breakthrough in rocket technology with new carbon-carbon nozzle for engines

Representative image.

The potential impact of this development is significant, particularly for ISRO's workhorse launcher, the Polar Satellite Launch Vehicle (PSLV)

The Indian Space Research Organisation (ISRO) has announced a significant breakthrough in rocket technology with the development of a new lightweight Carbon-Carbon (C-C) nozzle. This innovation is set to dramatically enhance the performance and payload capacity of ISRO's launch vehicles, marking a pivotal advancement in its space exploration capabilities.

The innovation originates from ISRO's Vikram Sarabhai Space Centre (VSSC) located in Thiruvananthapuram.

According to information provided by ISRO in a statement, the development involved the use of advanced Carbon-Carbon composites to create a nozzle divergent, distinguished by its exceptional mechanical properties at high temperatures. This new nozzle divergent is characterized by its low density, high specific strength, and excellent stiffness—attributes that are crucial for enhancing the efficiency of rocket engines.

The newly designed C-C nozzle is anticipated to significantly elevate vital parameters of rocket engines, such as thrust levels, specific impulse, and thrust-to-weight ratios.

According to ISRO, the potential impact of this development is significant, particularly for its workhorse launcher, the Polar Satellite Launch Vehicle (PSLV). The PS4, the fourth stage of the PSLV, currently employs twin engines with nozzles made from Columbium alloy.

"However, by replacing these metallic divergent nozzles with C-C counterparts, a mass reduction of approximately 67% can be achieved. This substitution is projected to increase the payload capability of the PSLV by 15 kg, a notable enhancement for space missions," ISRO said.

Durability and Resistance Features

One of the standout features of the C-C nozzle is its specialized anti-oxidation coating made of Silicon Carbide. This coating significantly extends the operational limits of the nozzle in oxidizing environments, a common challenge in rocket operations. It reduces thermally induced stresses and enhances corrosion resistance, which together allow for extended operational temperature limits. These enhancements ensure that the nozzle remains durable and effective in the hostile environments of space.

The efficacy and reliability of the new nozzle were rigorously tested at the ISRO Propulsion Complex (IPRC) located in Mahendragiri, Tamil Nadu. The testing protocol included a 60-second hot test conducted on March 19, 2024, followed by a more extended 200-second hot test on April 2, 2024. These tests confirmed the nozzle’s performance and hardware integrity, with temperatures reaching up to 1216K, aligning with the predicted outcomes and demonstrating robust system capabilities.

The development of the new nozzle was a result of a collaborative effort across multiple ISRO centres. The Liquid Propulsion Systems Centre (LPSC) at Valiamala near Thiruvananthapuram played a critical role in designing and configuring the tests. Meanwhile, the IPRC was responsible for the instrumentation and execution of these tests at their High-Altitude Test (HAT) facility. This teamwork integrates ISRO’s technological advancements with its mission preparations.

This technological breakthrough significantly enhances the capabilities of ISRO’s workhorse launcher, the PSLV. It not only promises to support more ambitious space missions but also paves the way for advancements in other satellite launch vehicles. By increasing payload capacity, ISRO can undertake more complex and weightier missions, potentially including manned space flights and interplanetary explorations.

The successful development and testing of the Carbon-Carbon nozzle demonstrates ISRO's ongoing commitment to innovation and excellence in space technology. This breakthrough is expected to play a critical role in future explorations, contributing to ISRO's growing reputation as a leader in global space research and exploration.

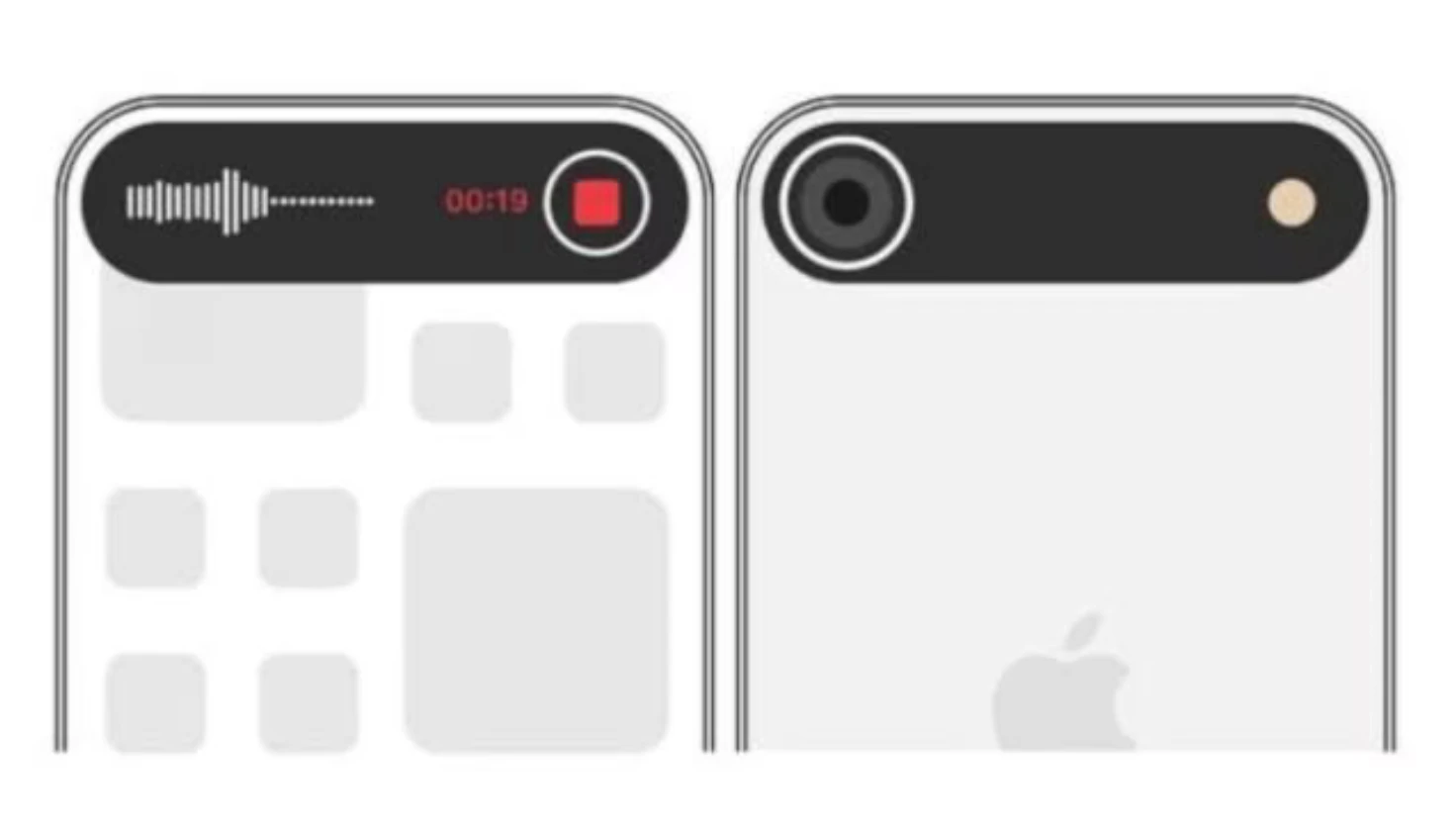

iPhone 17 Series Set for Significant Dynamic Island Upgrade

Anticipation builds for the iPhone 17 series, featuring an enhanced Dynamic Island in September 2025, promising a more integrated user experience.

| 2025-07-16

Comparative Analysis of Vivo X Fold 5 and Samsung Z Fold 7 Devices

A detailed comparison of specifications, features, and pricing for the Vivo X Fold 5 and Samsung Z Fold 7 foldable smartphones.

| 2025-07-16

Samsung Galaxy S26 Ultra to Feature Innovative Display Technology

Samsung's upcoming Galaxy S26 Ultra may revolutionise display tech with CoE OLED, enhancing brightness and battery efficiency.

| 2025-07-16

“When precision meets passion and technology meets tenacity”: PM Modi congratulates Crew-9 astronauts on return to Earth

PM Modi describes NASA astronaut Sunita Williams as a trailblazer and an icon

| 2025-03-19

‘Eliminate bias, develop open source systems that enhance trust and transparency’: PM Modi at AI Action Summit in Paris

The loss of jobs is AI’s most feared disruption, says PM Modi

| 2025-02-11