Apple’s Potential Exit from India May Spark Domestic Manufacturing Reform: GTRI

The GTRI report presents Apple’s possible exit not as a setback but as a moment for introspection and policy correction.

Apple shifting iPhone assembly from India to the US may hurt profits but could push India toward deeper manufacturing, says Global Trade Research Initiative.

A potential shift in Apple Inc.’s iPhone assembly operations from India to the United States could lead to higher costs for the tech giant but might also encourage India to invest more deeply in its domestic manufacturing ecosystem, according to a new report by the Global Trade Research Initiative (GTRI).

The report suggests that while India may lose low-paying jobs if Apple relocates its assembly operations, the broader economic impact could be more significant for Apple itself, with rising production costs potentially threatening its profitability.

Minimal Gains, Heavy Subsidies

Currently, India earns less than USD 30 from each iPhone assembled locally, much of which is returned to Apple through production-linked subsidies. Ajay Srivastava, co-founder of GTRI, noted that India’s actual value addition in the iPhone supply chain is minimal, and the government’s efforts to accommodate global firms like Apple have sometimes come at the expense of domestic manufacturing ambitions.

“To accommodate Apple, India is lowering tariffs on crucial components such as chipsets, screens, and batteries, which hurts local manufacturers attempting to build a native supply chain,” Srivastava said.

According to the report, India’s reliance on foreign players for assembly-based exports may be unsustainable. Should Apple shift production, it might force India to pivot from low-value assembly lines to higher-value manufacturing in areas such as semiconductors, batteries, and advanced displays.

Cost Implications for Apple

Relocating iPhone assembly from India to the United States would significantly raise Apple’s manufacturing costs. The average monthly wage for an assembly worker in India is around USD 230, compared to over USD 2,900 under US minimum wage laws. As a result, the per-unit cost of assembling an iPhone would jump from approximately USD 30 to USD 390.

This shift would reduce Apple’s profit margin on each device from USD 450 to just USD 60, unless the company increases retail prices—a move that could affect consumer demand in the United States, its largest market.

Global Value Chain and Employment Impact

Despite the perception of iPhones as American-made products, their value chain spans the globe. For a USD 1,000 iPhone, the breakdown includes USD 150 going to Taiwanese firms for chip fabrication, USD 90 to South Korean companies for displays and memory, and USD 85 to Japanese suppliers for camera modules. US component manufacturers such as Qualcomm and Broadcom account for about USD 80.

Manufacturing countries like India and China, responsible primarily for final assembly, receive less than 3% of the iPhone’s retail value—around USD 30 per device. However, these operations generate significant employment. Apple’s supply chain currently employs around 60,000 workers in India and nearly 300,000 in China.

According to GTRI, this job creation potential is a likely factor behind US President Donald Trump’s recent call for Apple to return its assembly operations to American soil.

Trump’s Pressure and Indian Response

During a business event in Doha on 15 May, President Trump publicly urged Apple CEO Tim Cook to halt expansion in India, saying, “I don’t want you building in India... They can take care of themselves.” The comment has raised questions about whether the statement was aimed at influencing trade negotiations or signalling a broader shift in US industrial policy.

Apple has not officially responded to the remarks. Meanwhile, a senior official from India’s Ministry of Commerce stated that multinational corporations make decisions based on commercial considerations such as profitability and ecosystem strength.

“India has proven itself as a competitive and stable destination for global manufacturing,” the official said, highlighting the country’s market access, skilled workforce, and policy continuity as key advantages.

Mixed Views Among Experts

While GTRI views a potential Apple exit as a long-term opportunity for India to restructure its industrial base, others disagree. Renowned economist Biswajit Dhar argued that losing Apple could harm India's ambitions.

“We have been dreaming about value addition for decades,” Dhar said. “If Apple remains committed, there’s a chance that its component suppliers may also relocate to India, helping build a more complete manufacturing ecosystem.”

He added that past examples, such as the automotive industry, demonstrate how long-term commitments from major firms can lead to the growth of domestic supplier networks.

India’s Export Growth in Electronics

India’s electronics exports have risen sharply, increasing from USD 23.57 billion in the financial year 2022–23 to USD 38.56 billion in 2024–25. This surge, driven by the Production Linked Incentive (PLI) scheme and foreign investments, underscores the growing importance of the sector.

Electronics recorded the highest export growth rate—over 32% in the past year. Key markets include the United States, United Arab Emirates, Netherlands, United Kingdom, and Italy.

The Future of India’s Manufacturing Policy

India’s strategic ambitions to become a global electronics hub have led to a reassessment of its manufacturing priorities. While attracting foreign investment remains critical, policymakers face the challenge of balancing assembly-based exports with the development of indigenous capabilities in high-tech manufacturing.

The GTRI report presents Apple’s possible exit not as a setback but as a moment for introspection and policy correction. Whether India seizes this opportunity may determine the future of its role in the global electronics value chain.

Reliance Retail acquires Kelvinator, The Coolest One

Reliance Retail has purchased the Kelvinator brand from Electrolux for nearly ₹160 crore, aiming to strengthen its position in India's consumer durables market.

| 2025-07-19

Saiyyara has shattered every myth about launching newcomers. No big names, no big PR

Madhur Bhandarkar praises debut film 'Saiyaara' for its raw talent and storytelling, marking a shift in Bollywood's approach to newcomers.

| 2025-07-19

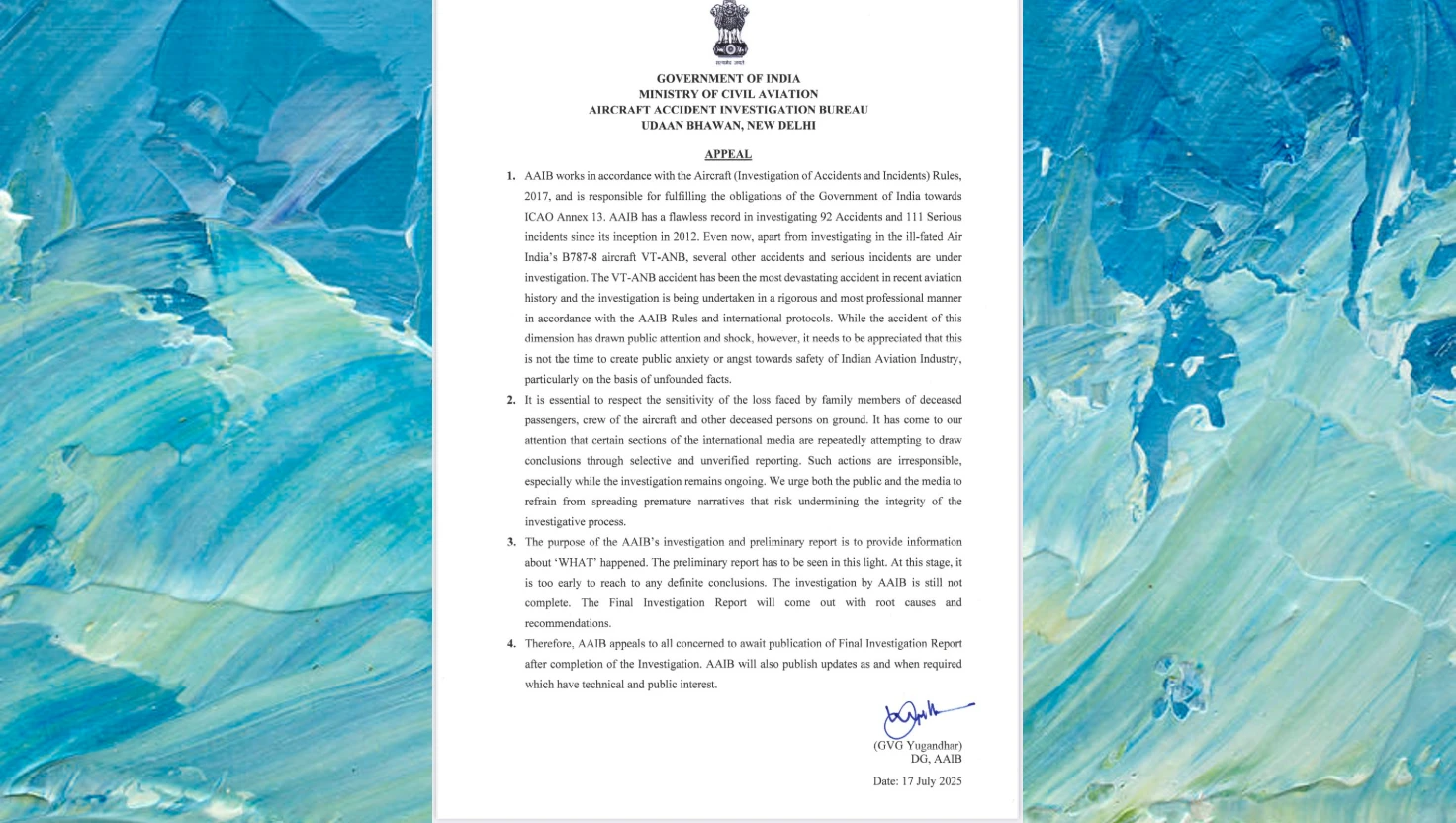

India slams reports blaming pilots for Air India crash

India's AAIB disputes US media assertions regarding Air India AI 171 crash, highlighting ongoing investigation and sensitivity towards victims' families.

| 2025-07-18

India Secures Four-Wicket Win in ODI Series Opener Against England

India achieves a four-wicket victory over England in the ODI series opener, led by Deepti Sharma's unbeaten 62 runs.

| 2025-07-17

Air India inspection claims no problems found with Boeing 787 fuel control switches

Air India has conducted thorough inspections of its Boeing 787 fuel control switches, reporting no problems following a DGCA directive.

| 2025-07-17