India Approves Rs 3,700 Crore Semiconductor Plant in Uttar Pradesh

The Cabinet has approved the establishment of one more semiconductor unit under India Semiconductor Mission in Uttar Pradesh.

India's Cabinet has cleared a Rs 3,700 crore HCL-Foxconn semiconductor plant in Uttar Pradesh to produce display driver chips, boosting domestic chip manufacturing.

India’s Union Cabinet, chaired by Prime Minister Narendra Modi, has approved the establishment of a Rs 3,700 crore semiconductor manufacturing facility in the northern state of Uttar Pradesh. The new plant, a joint venture between Indian technology company HCL and Taiwan-based electronics manufacturer Foxconn, will produce display driver chips used in mobile phones, laptops, automotive systems, and other digital devices.

The announcement was made on Wednesday by Indian Minister for Information and Broadcasting Ashwini Vaishnaw, who described the development as a significant step in advancing the country’s semiconductor capabilities under the India Semiconductor Mission (ISM), a government initiative aimed at building a robust domestic chip industry.

Advanced Chip Facility Near Delhi Airport Hub

The new facility will be located near the upcoming Jewar International Airport, within the Yamuna Expressway Industrial Development Authority (YEIDA) region of Uttar Pradesh. The plant is designed to process 20,000 semiconductor wafers per month and produce up to 36 million chips monthly.

The chips, known as display driver integrated circuits (ICs), are critical for managing how images and information appear on digital screens. These components are essential across a wide array of products, including smartphones, tablets, televisions, personal computers, medical devices, and in-vehicle displays.

"This is a very advanced technology that is being set up," said Minister Vaishnaw during a press briefing. "These chips control the function and format of content on screens, and once this unit is operational, it could lead to further investments, including a display panel manufacturing plant."

The plant is expected to be operational by 2027 and is projected to generate approximately 2,000 direct jobs. It forms part of the Indian government’s broader efforts to reduce dependency on imported semiconductors and position the country as a global hub for electronics manufacturing.

Strategic Importance and Broader Impact

This is the sixth semiconductor unit approved under India’s national semiconductor strategy. According to the Cabinet statement, five other such facilities are currently in advanced stages of development.

"The semiconductor industry is now shaping up across the country," the Cabinet note stated. "World-class design facilities have come up in many states. State governments are vigorously supporting these initiatives by partnering with design firms."

Currently, around 270 academic institutions and 70 start-ups across India are engaged in developing cutting-edge chip design technologies. As part of this ecosystem, the Semi-Conductor Laboratory (SCL) in Mohali has facilitated the successful development of approximately 20 chip prototypes designed by Indian students.

Foxconn, formally known as Hon Hai Precision Industry Co., is the world’s largest electronics contract manufacturer and is best known for assembling Apple’s iPhones. HCL, a homegrown Indian multinational, has a long history in IT services and hardware development. The partnership brings together deep global manufacturing experience and local industrial expertise.

Expanding Semiconductor Ecosystem in India

The semiconductor initiative is seen as a key pillar of Prime Minister Modi’s “Atmanirbhar Bharat” (Self-Reliant India) campaign, aimed at strengthening domestic capabilities in strategic industries.

Several major global suppliers have begun expanding their presence in India to support the anticipated growth in semiconductor production. Leading chipmaking equipment firms such as Applied Materials and Lam Research now operate in the country, while critical gas and chemical suppliers—including Merck, Linde, Air Liquide, and Inox—are scaling up operations to meet future demand.

Minister Vaishnaw underscored the broader impact of the sector, stating, “Semiconductors are basic components. It will have a multiplier effect on the entire electronics manufacturing in the country.”

The electronics manufacturing sector in India currently employs around 2.5 million people. Analysts expect that as domestic chip production ramps up, it will lead to an increase in high-skill employment, foreign investment, and technological innovation.

India’s Semiconductor Push

India’s push for domestic chip manufacturing comes amid global efforts to diversify semiconductor supply chains, which were severely disrupted during the COVID-19 pandemic. Countries including the United States, South Korea, and members of the European Union have also launched large subsidy programmes to attract chipmakers.

The India Semiconductor Mission, launched in 2021, offers financial incentives to attract global players and promote homegrown capability in chip design, fabrication, and assembly. The latest HCL-Foxconn venture is the latest example of how public-private partnerships are being used to accelerate progress in this strategically vital industry.

As India continues to expand its chip-making ecosystem, it aims to not only reduce dependence on foreign imports but also emerge as a key player in the global semiconductor value chain.

The announcement was made on Wednesday by Indian Minister for Information and Broadcasting Ashwini Vaishnaw, who described the development as a significant step in advancing the country’s semiconductor capabilities under the India Semiconductor Mission (ISM), a government initiative aimed at building a robust domestic chip industry.

Advanced Chip Facility Near Delhi Airport Hub

The new facility will be located near the upcoming Jewar International Airport, within the Yamuna Expressway Industrial Development Authority (YEIDA) region of Uttar Pradesh. The plant is designed to process 20,000 semiconductor wafers per month and produce up to 36 million chips monthly.

The chips, known as display driver integrated circuits (ICs), are critical for managing how images and information appear on digital screens. These components are essential across a wide array of products, including smartphones, tablets, televisions, personal computers, medical devices, and in-vehicle displays.

"This is a very advanced technology that is being set up," said Minister Vaishnaw during a press briefing. "These chips control the function and format of content on screens, and once this unit is operational, it could lead to further investments, including a display panel manufacturing plant."

The plant is expected to be operational by 2027 and is projected to generate approximately 2,000 direct jobs. It forms part of the Indian government’s broader efforts to reduce dependency on imported semiconductors and position the country as a global hub for electronics manufacturing.

Strategic Importance and Broader Impact

This is the sixth semiconductor unit approved under India’s national semiconductor strategy. According to the Cabinet statement, five other such facilities are currently in advanced stages of development.

"The semiconductor industry is now shaping up across the country," the Cabinet note stated. "World-class design facilities have come up in many states. State governments are vigorously supporting these initiatives by partnering with design firms."

Currently, around 270 academic institutions and 70 start-ups across India are engaged in developing cutting-edge chip design technologies. As part of this ecosystem, the Semi-Conductor Laboratory (SCL) in Mohali has facilitated the successful development of approximately 20 chip prototypes designed by Indian students.

Foxconn, formally known as Hon Hai Precision Industry Co., is the world’s largest electronics contract manufacturer and is best known for assembling Apple’s iPhones. HCL, a homegrown Indian multinational, has a long history in IT services and hardware development. The partnership brings together deep global manufacturing experience and local industrial expertise.

Expanding Semiconductor Ecosystem in India

The semiconductor initiative is seen as a key pillar of Prime Minister Modi’s “Atmanirbhar Bharat” (Self-Reliant India) campaign, aimed at strengthening domestic capabilities in strategic industries.

Several major global suppliers have begun expanding their presence in India to support the anticipated growth in semiconductor production. Leading chipmaking equipment firms such as Applied Materials and Lam Research now operate in the country, while critical gas and chemical suppliers—including Merck, Linde, Air Liquide, and Inox—are scaling up operations to meet future demand.

Minister Vaishnaw underscored the broader impact of the sector, stating, “Semiconductors are basic components. It will have a multiplier effect on the entire electronics manufacturing in the country.”

The electronics manufacturing sector in India currently employs around 2.5 million people. Analysts expect that as domestic chip production ramps up, it will lead to an increase in high-skill employment, foreign investment, and technological innovation.

India’s Semiconductor Push

India’s push for domestic chip manufacturing comes amid global efforts to diversify semiconductor supply chains, which were severely disrupted during the COVID-19 pandemic. Countries including the United States, South Korea, and members of the European Union have also launched large subsidy programmes to attract chipmakers.

The India Semiconductor Mission, launched in 2021, offers financial incentives to attract global players and promote homegrown capability in chip design, fabrication, and assembly. The latest HCL-Foxconn venture is the latest example of how public-private partnerships are being used to accelerate progress in this strategically vital industry.

As India continues to expand its chip-making ecosystem, it aims to not only reduce dependence on foreign imports but also emerge as a key player in the global semiconductor value chain.

Reliance Retail acquires Kelvinator, The Coolest One

Reliance Retail has purchased the Kelvinator brand from Electrolux for nearly ₹160 crore, aiming to strengthen its position in India's consumer durables market.

| 2025-07-19

Saiyyara has shattered every myth about launching newcomers. No big names, no big PR

Madhur Bhandarkar praises debut film 'Saiyaara' for its raw talent and storytelling, marking a shift in Bollywood's approach to newcomers.

| 2025-07-19

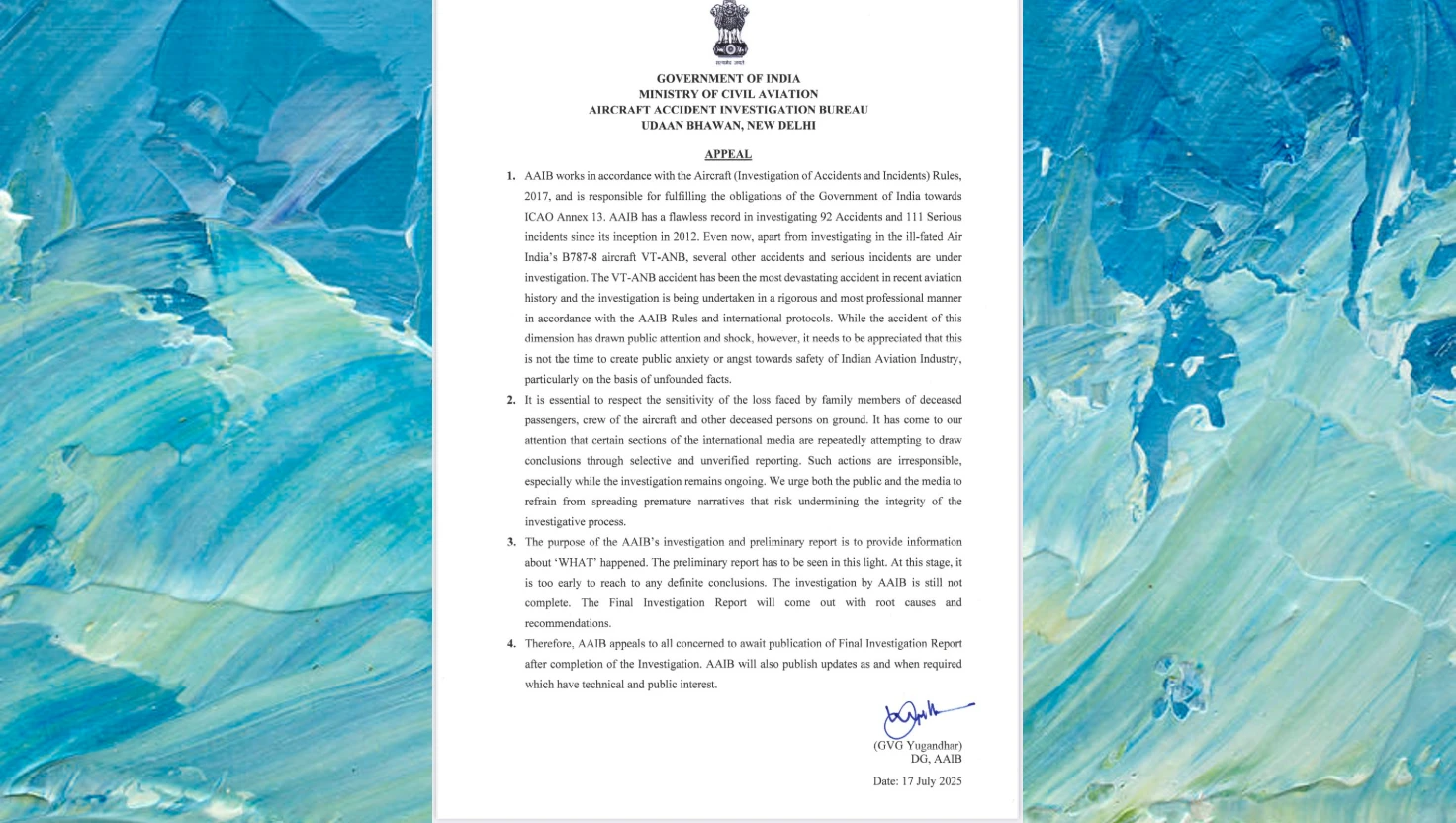

India slams reports blaming pilots for Air India crash

India's AAIB disputes US media assertions regarding Air India AI 171 crash, highlighting ongoing investigation and sensitivity towards victims' families.

| 2025-07-18

India Secures Four-Wicket Win in ODI Series Opener Against England

India achieves a four-wicket victory over England in the ODI series opener, led by Deepti Sharma's unbeaten 62 runs.

| 2025-07-17

Air India inspection claims no problems found with Boeing 787 fuel control switches

Air India has conducted thorough inspections of its Boeing 787 fuel control switches, reporting no problems following a DGCA directive.

| 2025-07-17